If you’ve been working with a prosumer-grade benchtop mitre saw, like an AEG, Ozito, DeWalt, or Makita, chances are it has served you well—until it didn’t. Perhaps you’ve noticed inconsistencies in your cuts, struggled with alignment issues for corner cuts, had a safety scare or felt like the machine couldn’t keep up with your workload. That’s often the turning point when people realise it’s time to upgrade and invest in equipment built for the demands of a workshop.

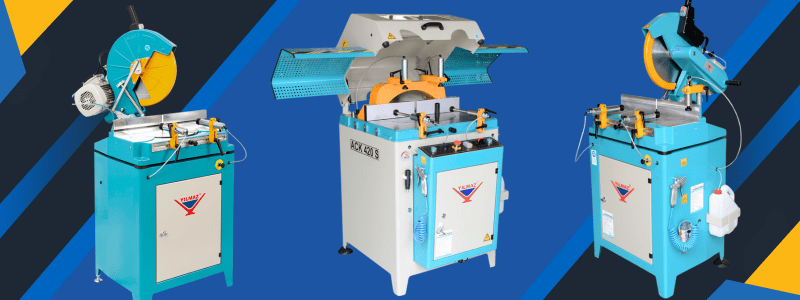

At AMS, the Yilmaz KD350PS and KD400PS are our most popular entry-level mitre drop saws and for those looking to step up to an upcut mitre saw the ACK420 is many customers preferred model. These machines set the benchmark for professional cutting and build quality at a price that delivers exceptional value for money.

1. Build Quality That Means Business

Prosumer machines are designed to be affordable, catering to DIYers and semi-professionals. Their construction often involves lightweight materials to keep costs down, making them portable but less robust overall. Without a solid base, accuracy and repeatability of cuts become a serious issue. Cheaper parts lead to more downtime when dealing with repairs and replacing parts that break or burn out quickly.

In contrast, the Yilmaz KD350PS, KD400PS and ACK420 are engineered for commercial environments. Built with a heavy-duty cast aluminium base and rigid components that minimise vibration during operation. This directly impacts the accuracy and consistency of your cuts, especially when working with tough materials like aluminium and non-ferrous metals.

AMS has used, sold and serviced the Yilmaz range for over twenty years. We have the technical expertise to maintain your Yilmaz machine and a spare parts warehouse to ensure minimal downtime.

Cast iron tabletop of Yilmaz machines

Horizontel pneumatic clamps on KD range

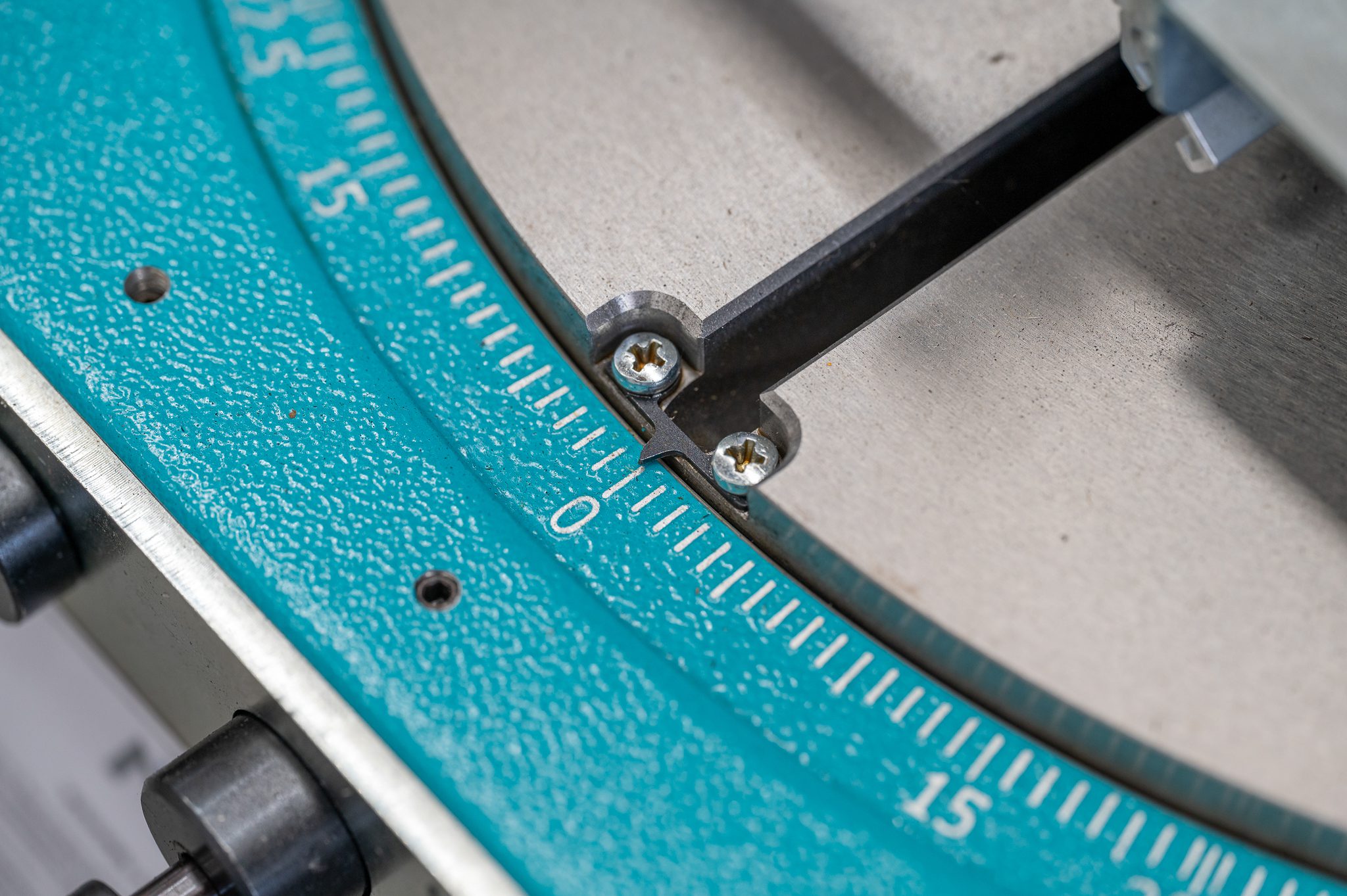

2. Precision That’s Consistent, Not Occasional

With consumer mitre saws, achieving a perfect cut feels like a balancing act. Spending extra time adjusting materials, re-checking angles, and dealing with slight flexes in the bevel sliding mechanism. While they can deliver accurate cuts, maintaining that precision over time—especially under heavy use—is exceptionally challenging.

The Yilmaz KD range is designed to deliver repeatable, high-precision cuts every time. Its powerful clamping system securely holds materials, reducing the risk of mid-cut movement. With locking mechanisms, you can mitre 45º left and right, so you don’t have to second-guess your settings. Whether cutting once or a hundred times, you’ll get the same result—accurate, clean, and reliable.

3. Efficiency That Saves Time (and Money)

Time is money in any workshop. Prosumer tools can slow you down with limitations on cutting capacity, motor power, and the need for constant adjustments. Their motor and saw blades handle basic tasks well, but when cutting through thicker or denser materials, you’ll feel the strain—literally.

The ACK420 is built to handle demanding workflows. Its powerful motor and larger blade capacity mean faster cuts with less effort. Adding an in and outfeed roller conveyor helps improve material handling. Combined with a maxi digital stop, you have a complete professional setup that will serve you well for years.

ACK420 with digital measuring stop and roller convey accessories

4. Long-Term Value That Pays Off

The upfront cost of a professional machine is higher than that of a consumer mitre saw. But consider the long-term picture. How much time do you lose with inaccurate cuts, rework, or downtime due to maintenance issues?

Workshop-grade machinery is a wise upgrade and investment in efficiency, reliability, and professional-grade results that can save you money over time.

Plus, with AMS’s expert support and readily available spare parts, you’re not just buying a machine—you’re gaining a partner committed to keeping your operations running smoothly.

Ready to Make the Switch?

If you’re tired of fighting with machinery that cannot meet your demands, contact our friendly and knowledgeable team to chat about the best solutions to your aluminium-cutting problems.