In today’s competitive manufacturing industry, workshops increasingly rely on skilled operators to deliver consistent, high-quality products efficiently. But what happens when a key team member leaves? Sudden gaps in expertise can disrupt workflows, delay projects, and increase costs. That’s where Pertici CNC machinery and AMS steps in. With Pertici offering hardware with built-in automation software to keep your operations running smoothly, and AMS providing training and technical servicing to minimise downtime and improve workshop efficiency.

Automation Designed for Simplicity

Pertici CNC machining centres are renowned for their simple, user-friendly practical layout with the functionality of one machine that can do a thousand jobs. Running P-CAM software, these machines simplify complex processes such as milling, drilling, tapping, and end milling by automating the movement and tool selection of the 4-axis or 5-axis electro-head, depending on the model.

P-CAM software has been developed to improve workshop efficiency and future-proof by storing required project information. Once project parameters are input, the machine allows less experienced team members to use the intuitive interface to operate the machines effectively instead of having one skilled employee do the workflow manually, which can lead to issues should that employee be absent.

Consistent Quality, Every Time

A Pertici CNC machine can recall stored parameters and deliver thousands of uniform cuts within 0.1mm +/-. Each output maintains the same high-quality standard, regardless of the operator’s skill level.

The result? There is no drop in customer satisfaction or output standards, even during challenging times.

Complex Projects Simulated

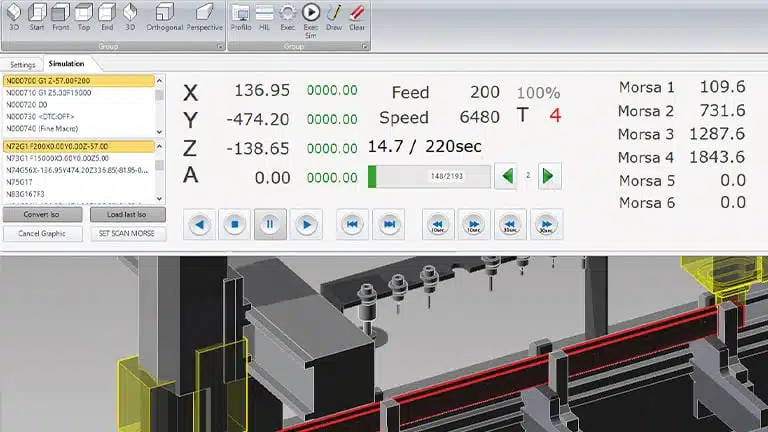

The P-CAM platform includes P-simulation software that emulates the entire work cycle, returning a digital project output, including workpiece working time. This simulation enables workshops to test complex projects risk-free before committing time and materials to the first manufacturing run without requiring skilled labourers.

Engineered for Versatility and Adaptability

Pertici has engineered CNC machines to work with various materials across different industries, including manufacturing, construction, fabrication, marine, windows, and doors. Like upskilling an employee across workshop processes, Pertici ensures software updates to keep its machines adapting to workshops and industries’ evolving needs.

AMS By Your Side

Investing in a Pertici CNC machine gives you more than a dependable machine; you get 39 years of experience, advice and support from Danny, Josh, and the AMS team by your side.

We partner with you to provide pre-purchase guidance to help you select the best machine for your needs. We offer on-site and remote training and have in-house technical support for servicing, spare parts, and emergency callouts. The AMS team is committed to helping your workshop and machines run smoothly and efficiently.

Future-Proofing Your Workshop

Losing a skilled worker doesn’t have to spell disaster for your workshop. Pertici CNC machinery is designed to bridge the skills gap, offering intuitive, versatile, and reliable solutions that maintain workshop efficiency and quality. With these machines at the core of your operations, with the support of AMS, you can confidently navigate staffing challenges while staying ahead of the competition.

Partner with the Professionals at AMS

Since its founding in 1985, AMS has the experience and knowledge to guide you in finding the best aluminium machinery solutions for your business. We assist with machinery installation, training your team and ongoing servicing to support your crew and machines. We have long-term customer relationships and take pride in helping your business grow with the most effective machinery solutions.

If you’re looking for aluminium machinery solutions for your business or want to investigate how to streamline your workflow, contact us at 1300 736 556 or email [email protected]