Adopting advanced CNC machining technology is crucial for aluminium workshops seeking to boost efficiency, address labour shortages or skill gaps, improve quality standards, and future-proof machinery. Pertici’s P527 Premium 5-axis CNC machining centre is an excellent investment that significantly streamlines processes while delivering unmatched flexibility and precision in aluminium fabrication.

Integrated Efficiency: One Machine Does It All

Traditionally, workshops have utilised several machines to complete a single workflow. For instance, aluminium profiles are cut to length using a mitre saw, followed by separate routing, drilling, or milling operations on a CNC machining centre or template router. Each additional step requires more floor space and increases material handling, leading to longer processing times and a higher risk of errors or inaccuracies.

The Pertici P527 Premium addresses these challenges by combining machining capabilities into a single machine. It can handle aluminium bars up to 6.5 meters long and efficiently performs routing, milling, drilling, tapping, and precision cutting operations. The P527 range eliminates the need for multiple setups, delivers accurate and repeatable cuts within a smaller footprint, and gives your workshop a competitive advantage.

Why 5-Axis is Better than 3- and 4-Axis

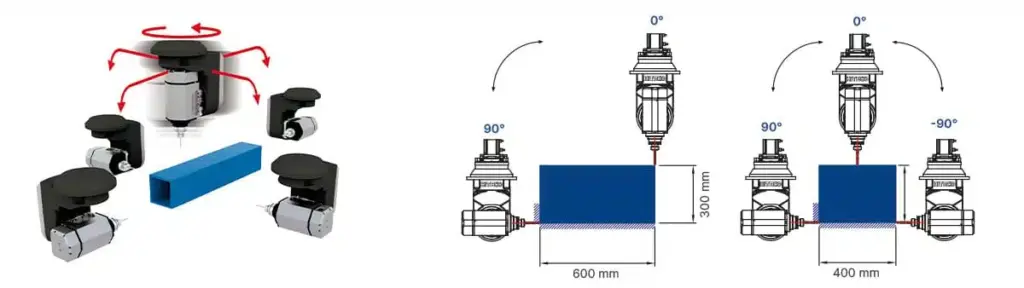

Producing complex shapes with a 3- or 4-axis machine typically requires multiple setups, and repositioning the aluminium increases the risk of inaccuracies. Five-axis machining allows the cutting tool to move across three linear axes (X, Y, Z) and two rotational axes (A, C).

A Pertici 5-axis CNC machine can machine from +/-90° for the A-axis to +/-320° for the C-axis, allowing workshops to easily create intricate features like compound angles, curved surfaces, and complex geometries. This capability is crucial for window and door manufacturing industries, where precise and complex profile cuts are common.

5-axis Precision Made Easy with P-Cam Software

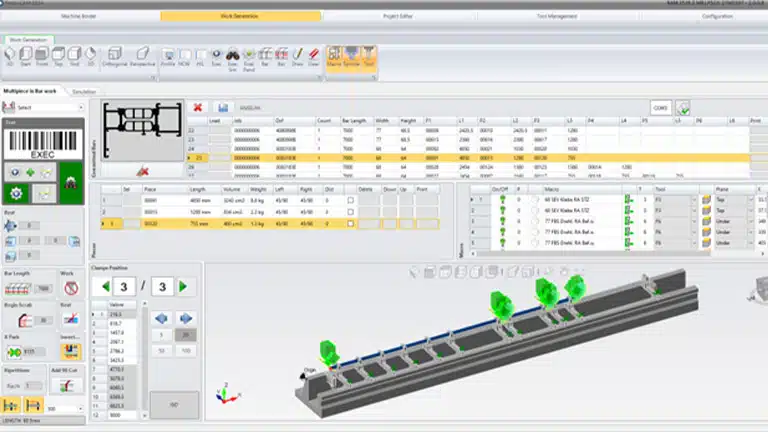

To control and simplify the power of 5-axis machining, Pertici has developed intuitive CNC software explicitly designed for aluminium fabrication. This software bridges skill gaps in workshops by being easily programable and instinctive to use by less experienced employees.

With a user-friendly graphical interface, Pertici CNC machines can recall stored parameters and deliver thousands of uniform cuts within 0.1mm +/-. Each output maintains the same high-quality standard, regardless of the operator’s skill level.

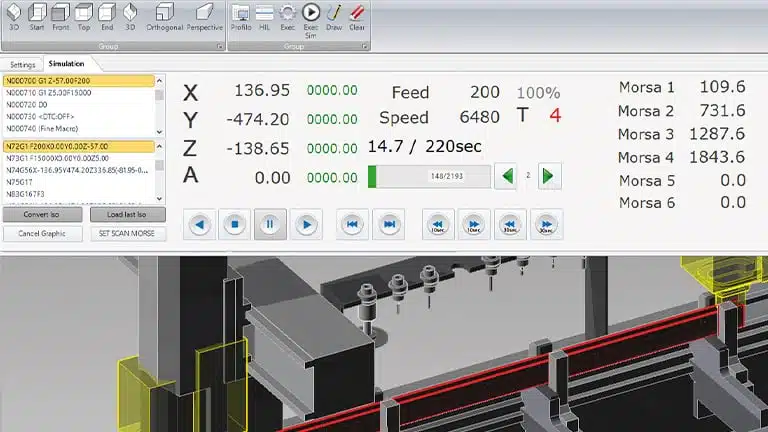

The P-CAM platform includes P-simulation software that emulates the entire work cycle, outputting a digital project, including workpiece working time. This simulation enables workshops to test complex projects risk-free before committing time and materials to the first manufacturing run without requiring skilled labourers.

25 Year Partnership Between Pertici and AMS

When choosing the Pertici P527 Premium (or any Pertici machine), you are gaining more than an advanced machine—you are gaining the trusted support of AMS. With over 25 years of experience using, selling and servicing Pertici machinery, we are here to help you integrate Pertici machinery into your workflow and maximise your investment.

Our experienced technicians are available for in-person and remote support. We’re committed to making your machinery run efficiently, from setup and training to regular maintenance, troubleshooting, and repairs. With AMS, you’ll have a dedicated local partner who’s committed to your ongoing productivity and long-term success, ensuring your investment in the Pertici P527 Premium delivers value day after day.

Partner with the Professionals at AMS

Since its founding in 1985, AMS has the experience and knowledge to guide you in finding the best aluminium machinery solutions for your business. We assist with machinery installation, training your team and ongoing servicing to support your crew and machines. We have long-term customer relationships and take pride in helping your business grow with the most effective machinery solutions.

If you’re looking for aluminium machinery solutions for your business or want to investigate how to streamline your workflow, contact us at 1300 736 556 or email [email protected]