Manual jobs like routing and punching still have their place, but they slow down production. Using wall-mounted templates and switching between machines for different cuts takes time, increases handling, and adds risk of error.

In 2026, it’s time to work smarter!

By switching to CNC machining, you can eliminate repetitive handling, reduce errors, and streamline your entire process. The Pertici P104 combines routing, drilling, tapping, and end milling in one setup. With programmable control and repeatable accuracy, it simplifies your workflow and replaces outdated manual tasks.

This is how you bring your workshop into the new century.

The Problem with Manual Setups

If your current workflow involves any of the following, it may be holding your business back:

- Templates stuck to the wall for different cuts

- Manual copy routing with limited accuracy

- Switching between multiple machines for drilling, routing, and milling

- High risk of human error, rework, or inconsistent quality

- Time-consuming changeovers and repetitive setups

- Heavy reliance on skilled operators

- Inefficient use of workshop floor space

These outdated methods not only slow down production, but also drive-up labour costs and limit your ability to take on new projects quickly. They reduce your workshop’s flexibility, make it harder to scale, and can impact the consistency customers expect, especially as job variety and volumes increase.

Why CNC is the Smarter Choice

A CNC profile router like the Pertici P104 simplifies your workflow by replacing multiple manual machines with one intelligent and automated system.

- Program once and repeat thousands of times with no loss in accuracy

- Reduce labour and training time with easy-to-use PCAM software

- Improve safety by removing manual handling and positioning

- Eliminate setup downtime between jobs

- Maintain consistent part quality across every production run

- Free up floor space by combining multiple operations into one machine

- Future-proof your business with scalable automation

Whether you are producing a single unit or running large batches, the P104 delivers precision and repeatability every time.

The Power of PCAM Software

At the heart of the P104 is the PCAM interface, the feature that truly sets it apart. Designed for simplicity and control, PCAM brings CNC programming within reach of any workshop, regardless of operator experience.

With PCAM software, you can:

✓ Import jobs from DXF, STEP, or NCX formats

✓ Create parametric jobs and custom macros

✓ Simulate tool paths and runtime before cutting

✓ Use built-in collision checks for safer operation

✓ Save jobs for repeat use and quick changeovers

✓ Visually preview operations to reduce errors

Forget handwritten notes or template codes, every job is programmed, visualised, and ready to repeat. Even operators with minimal experience can run jobs confidently thanks to its user-friendly design.

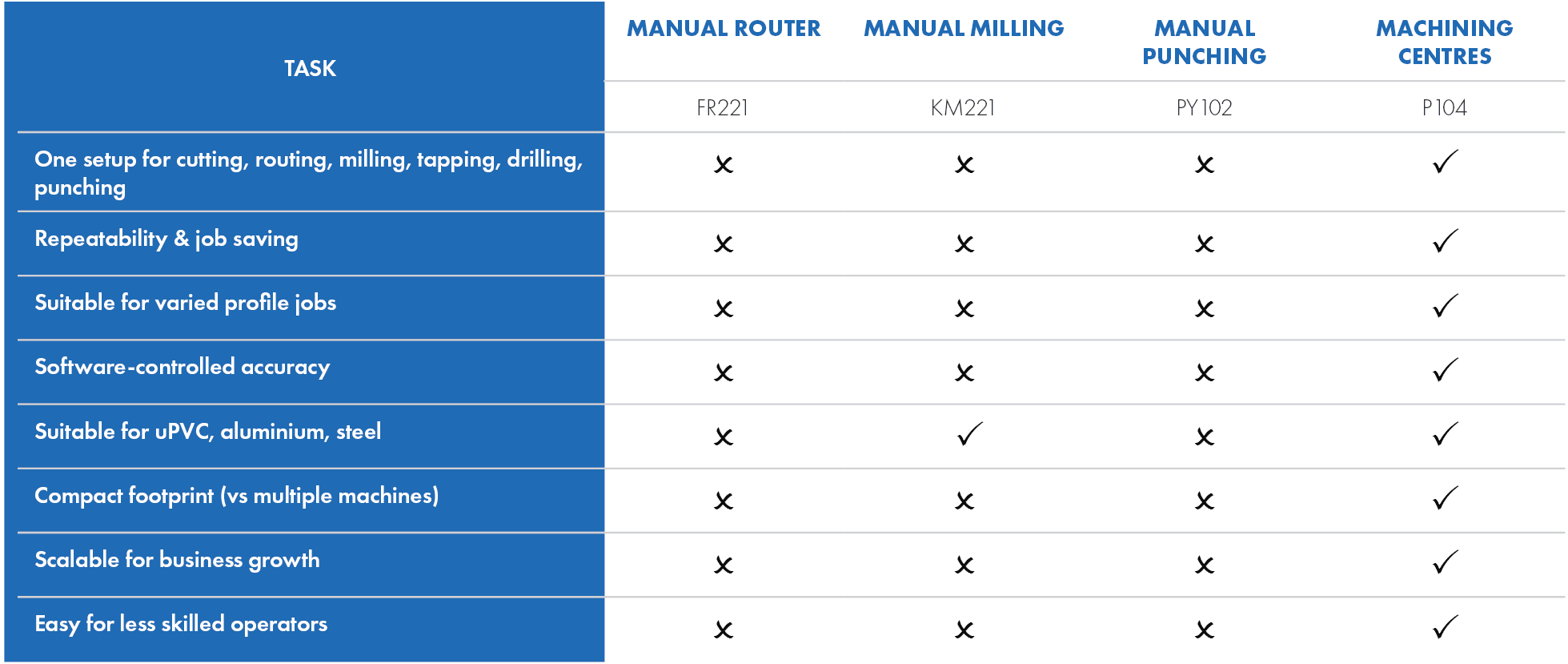

Comparison: CNC vs Traditional Machines

Bring Your Workshop into the New Century

If you are still relying on manual jobs and template setups, the Pertici P104 is your next step forward. Simplify your workflow, reduce your labour and scale your production with confidence.

Contact us for a demo or for more information about CNC Aluminium Machining Centre.