Managing long aluminium profiles can be time-consuming when your team relies on multiple machines. Each additional step increases the risk of error, adds handling time, and takes up more space in your workshop.

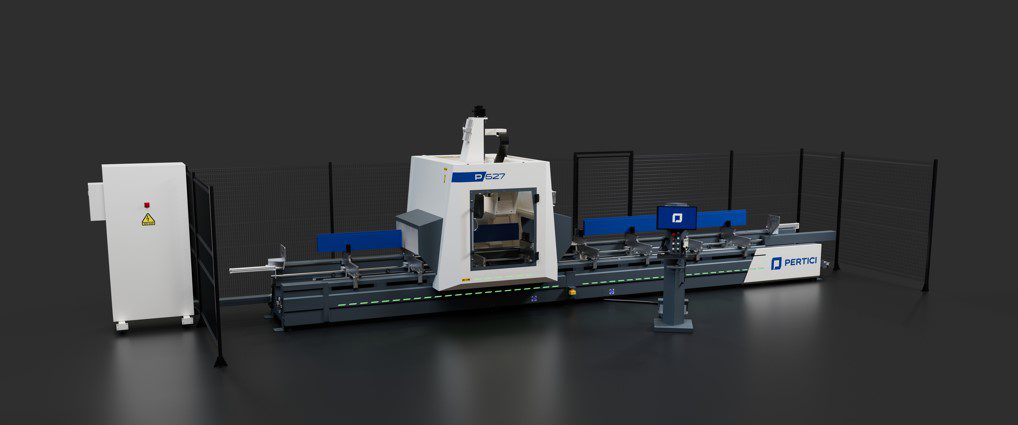

The Pertici P527 Premium CNC machining centre changes this process. It combines extended length capacity, five-axis control, intelligent automation, and intuitive PCAM software into one high-performance solution.

One Machine That Replaces Many

Many workshops still cut profiles on one machine, then move them to another for milling or drilling. This workflow increases handling and slows production. Over time, it can reduce accuracy and raise labour costs.

Instead, the P527 allows your team to complete all operations on a single machine. This includes cutting, drilling, notching, tapping, and milling. You only need to load the material once, which reduces setup time and minimises movement.

The 7.1-metre bed is ideal for processing full-length aluminium profiles, which is especially useful for jobs that involve long framing sections or large-scale architectural components.

Precision Cuts at Every Angle

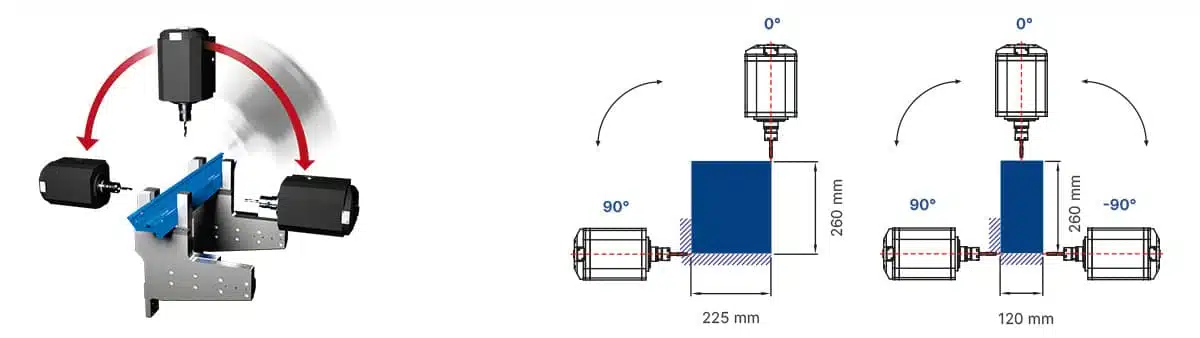

IThe P527 includes a five-axis electro-spindle head that allows full control in multiple directions. The A-axis rotates vertically by up to 90 degrees, and the C-axis rotates horizontally by up to 320 degrees. These movements give your team the ability to machine complex shapes from any angle.

This flexibility is ideal for fabricators producing compound cuts, notched brackets, or multi-faceted frames. Since the machine approaches the profile from any angle, you do not need to reposition or reclamp during the job. The P527 is a powerful machine leading to more consistent results and fewer errors.

PCAM Software: Smarter Control at Your Fingertips

Running the P527 is made easier with PCAM, Pertici’s intelligent machining software. The interface is visual and intuitive, so operators can set up jobs quickly and confidently.

The software supports:

- 3D visualisation of every job

- Built-in diagnostics on the P527

- CAD and CAM functionality with macro visualisation

- Importing of DXF, STEP, HIL, NCX, and NCW files

- Parametric programming with Boolean functions

- Built-in collision avoidance for added safety

- Storage and recall of job files for repeat work

Even complex machining tasks can be programmed in just a few steps. The PCAM reduces operator error, improves consistency, and keeps your workflow moving smoothly.

The P-Simulation module of the software previews the entire job before machining begins. You can calculate run time, visualise tool paths, and flag any potential collisions. This module allows your team to spot problems early and reduce waste while operating with greater confidence.

The P527 also features an automatic 16-position tool changer. This system speeds up multi-step jobs by switching tools without stopping the machine, which increases uptime and reduces idle time between processes.

In addition, the optical tool length probe automatically detects and calibrates each tool. It ensures greater accuracy across all operations and removes the need for manual tool measurements.

Together, these features make PCAM not just user-friendly, but a key part of delivering reliable and repeatable results.

Integrated Automation for Long Profiles

The P527 Premium includes automatic clamp positioning via the mobile carriage. During each job, clamps adjust themselves to the profile length and shape. A thoughtful automation that improves consistency and reduces manual adjustments between jobs.

The integrated straight cutting saw blade is fixed to the carriage. This enables straight profile cuts at full length without requiring a tool change. You can cut and machine long sections in one seamless pass.

For added capability, the machine can be fitted with an optional 500mm or 600mm saw blade. This upgrade allows for 90-degree cuts with greater speed and reliability.

Built for Large Jobs and Continuous Output

The P527 is built for industries that rely on long and complex aluminium profiles. These include:

- Truck and trailer manufacturing

- Façade and curtain wall framing

- Solar racking and aluminium support structures

- Custom architectural and industrial assemblies

Its strong steel frame, long bed, and automatic features make it ideal for the continuous and high-volume work of your workshop.

Backed by AMS – Before and After Installation

When you invest in the P527, you also receive the full support of AMS Aluminium Machinery Solutions. Our team works closely with you through every stage, from consultation and delivery to operator training and post-sale care.

Our support includes:

- Local spare parts from our Australian warehouse

- Servicing by qualified technicians

- Access to technical support, upgrades, and advice

With more than 40 years of experience, AMS is trusted by fabricators across the country. We understand the pressures of production and the value of keeping your machinery running smoothly.

See the P527 Premium in Action

Want to see the machine at work? Josh from AMS walks you through a real project using the PCAM software. In the demo, he shows how to simulate a job, position clamps, and run a complex toolpath on a full-length profile.

Ready to Make a Smarter Investment in Your Workshop?

The Pertici P527 Premium gives your workshop the flexibility to handle long profiles, perform complex machining, and reduce operator input. It simplifies programming, automates job setups, and delivers repeatable results with confidence.

Contact AMS today to schedule a demo or to learn how the P527 can support your business goals.