Workshops often expend significant capital on the best machinery they can afford for their workflow, neglecting to consider how investing in practical accessories that provide exceptional bang for your buck in your workshop through substantial productivity increases. This blog explores how investing a fraction of the cost of a new machine into a measuring stop will positively enhance your workflow.

The Problem: Manual Measuring Methods Lead to Waste and Error

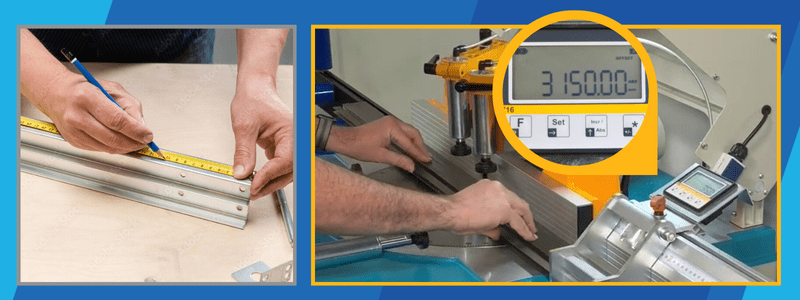

Imagine a workshop producing twelve identical lengths of aluminium cuts to be fabricated into a frame. Without measuring stops, workers rely on a tape measure to measure out each cut. This manual method, while traditional, is prone to human error. The simple act of positioning the tool, misreading small numbers, or even having the tool slip slightly can create mistakes. Over time, these minor inaccuracies accumulate, leading to increased costs through wasted materials, additional labour and time.

Manual Stops: A Cost-Effective Improvement

Adding a maxi manual measuring stop to a workflow provides consistency when measuring. Purposely designed for commercial environments with a robust aluminium rail, twin flag stops, and available in various sizes, manual stops operate within a margin of error—typically around ±1mm. This margin of error might be acceptable for some workshops, but a maxi digital stop offers ten times the accuracy for less than four times the cost.

The Maxi Digital Stop: Best Bang For Your Buck

With an accuracy of ±0.1mm, it offers the precision required for intricate projects where each cut must be perfect. Whether it’s window frames or more complex custom designs, a Maxi Digital Stop ensures that each piece fits together seamlessly.

The Maxi Digital Stop is outfitted with a large, easy-to-read, and highly precise digital readout. The digital interface reduces the risk of misreading or manual errors and ensures that even the most complex measurements can be consistently replicated accurately.

A Worthwhile Investment with Immediate Payoffs

When a workshop makes hundreds of cuts in a single day, even saving a few seconds per cut adds up quickly. From the first measurement, operators will notice increased productivity, fewer wasted materials, and fewer costly mistakes. Over time, this consistency leads to better project outcomes, reduced rework, and an enhanced reputation for delivering high-quality, precise work.

Precision, efficiency, reliability and consistency are critical to success in any workshop. The Maxi Digital Stop encapsulates all these aspects, ensuring that each cut is accurate, reducing the chance of mistakes, and improving overall productivity. Workshops that switch from manual measuring methods to digital stops will see immediate benefits, with fewer errors, less wasted material, and a more streamlined workflow.

Partner with the Professionals at AMS

In operation since 1985, AMS has the experience and knowledge to guide you on the best aluminium machinery solutions for your business. We assist with machinery installation, training your team and ongoing servicing to support your crew and machines. We have long-term customer relationships and take pride in helping your business grow with the most effective machinery solutions.

If you’re looking for aluminium machinery solutions for your business or want to investigate how to streamline your workflow, contact us at 1300 736 556 or email [email protected].