In aluminium fabrication, results depend on more than the machine itself. Accessories like coolant, router bits, mist kits and saw blades directly influence cut quality, tool life and overall efficiency.

AMS has been supplying workshops for decades with aluminium professionals across Australia. We see the difference the right accessories make, from reducing breakdowns to improving workshop output.

Here’s how these often-overlooked products form the backbone of high-performance aluminium machining.

Why Your Workshop Should Prioritise Accessories

Every part of the machining process matters. A workshop that invests in precision equipment but neglects accessory quality risks poor finishes, excessive vibration and premature tool failure.

Accessories support accuracy, cooling and cutting performance. They also help your machines operate at full potential, especially during longer production runs.

AMS supplies thousands of workshops nationwide with aluminium-specific consumables that make a measurable impact. The range is backed by technical support and fast dispatch.

Shop our aluminium accessories.

Top 4 Aluminium Machining Accessories and Why They Matter

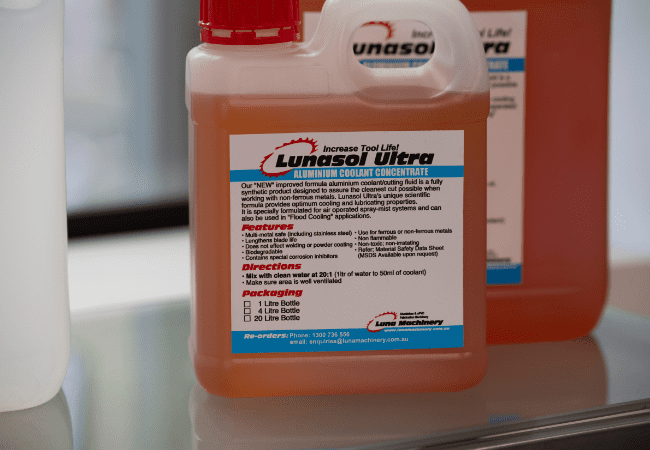

1. Aluminium Cutting Coolant

Coolant isn’t optional but essential for aluminium. Spray mist lubrication systems require coolant formulated to reduce heat and maintain mist quality.

AMS recommends Lunasol Ultra Aluminium Spray Mist Coolant, proven to reduce wear and support clean machining across various setups.

- Helps keep tools cool during high-speed cutting

- Improves finish on aluminium and non-ferrous materials

- Reduces friction and tool loading

2. Aluminium Router Bits

Router bits are critical for edge quality. When bits aren’t made for aluminium, they produce a rough-cut finish and wear out fast.

AMS stocks Solid Carbide Router Cutters suited for CNC routing machines, and High-Speed Steel Router Cutters designed for efficient routing in any high-speed aluminium router.

- Delivers clean and smooth cut finish

- Designed for high-speed performance

- Helps reduce rework and downtime

3. Spray Mist Lubrication Kits

Mist kits make your cooling system more efficient by directing coolant exactly where it’s needed. They improve both finish and tool life.

AMS spray mist kits are easy to retrofit and work with a wide range of machinery used in aluminium workshops.

- Minimises heat build-up and surface damage

- Boosts productivity with cleaner cuts

- Compatible with most saws, routers and mills

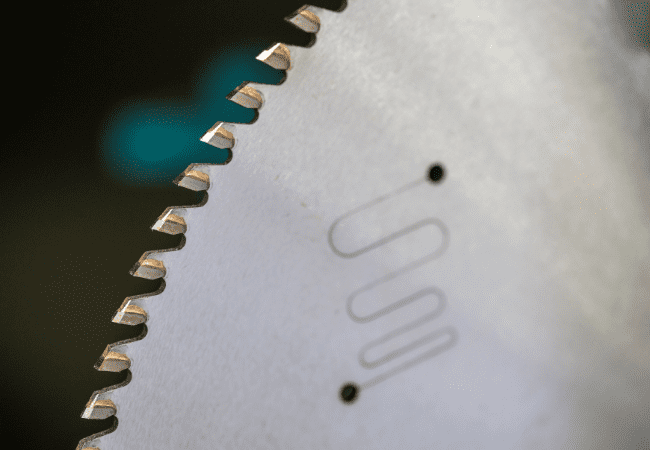

4. Aluminium Saw Blades

Aluminium cutting requires different blade geometry and coatings from those used for timber or steel. The right blade reduces burring, vibration and friction.

AMS carries high-quality blades for aluminium, with sizes to suit mitre saws, upcut saws and CNC saw systems.

- Delivers smooth, clean cuts

- Reduces vibration and heat for longer life

- Designed specifically for non-ferrous profiles

Avoid Downtime with the Right Consumables

Worn or incorrect accessories often cause:

- Poor edge finish

- Breakdowns from tool overheating

- Material waste

- Extended changeover times

A good machine can’t solve these issues without support from the right tooling and accessories. AMS helps reduce workshop downtime by keeping accessories in stock, advising on compatibility, and dispatching quickly across Australia.

How to Stay Ready All Year

Workshops that maintain steady output tend to follow a supply strategy. This avoids urgent reorders, helps plan servicing, and protects projects from stalling.

A simple restocking plan might include:

- 2+ spares for your most-used accessories

- Setting re-order levels in your system

- Ordering early before high-volume periods (e.g. pre-Christmas, EOFY)

AMS provides local stock with 1–2 business day dispatch, so workshops stay ready without delays.

Finish Strong with the Right Accessories

Accessories shape the performance of your machinery. Coolant, blades, bits and spray mist systems influence tool life, material finish and reliability across every job.

AMS supports workshops with expert advice, trusted aluminium machining accessories and fast nationwide delivery. When your team counts on accuracy and uptime, every part matters right down to the accessories.

Ready to Make a Smarter Investment in Your Workshop?

The Pertici P527 Premium gives your workshop the flexibility to handle long profiles, perform complex machining, and reduce operator input. It simplifies programming, automates job setups, and delivers repeatable results with confidence.

Contact AMS today to schedule a demo or to learn how the P527 can support your business goals.