In the realm of modern manufacturing, staying ahead of the curve is not just a choice but a necessity.

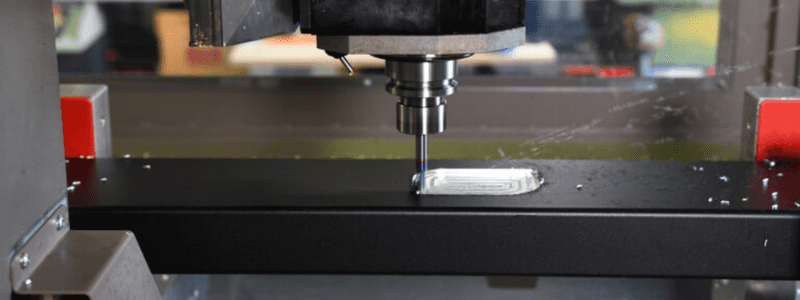

The dawn of automation has brought forth a new era of precision, efficiency, and innovation. For businesses leveraging aluminium cutting machinery, advancement has come in the shape of the CNC profile router. This cutting-edge advancement is not just an upgrade in technology but an investment and opportunity to reshape your business’ competitive edge.

Why Upgrade?

If your business relies on aluminium cutting solutions and is contemplating an upgrade in machinery, investing in a CNC profile router promises benefits and value. These include:

Automation: From Manual to Now

Automation has emerged as the driving force of progress, reshaping traditional manufacturing processes. Only a short time ago, aluminium cutting was a labour-intensive and time-consuming endeavour. Manual methods involving saws, drills, and templates were the norm, and using the latest technology still meant having someone manually feed the aluminium material into the machine. Upgrading to new machinery is a pivotal step for your business in embracing the transformative technology of today.

Efficiency: Time is Money

In any company, time is an expensive and precious commodity. An upgrade in machinery eliminates the need for labour-intensive manual operations, allowing your business to streamline your aluminium cutting processes. Swift and accurate, the CNC profile router drastically reduces lead times, enabling manufacturers to fulfil orders faster and more efficiently.

Precision: Elevating Quality at the Core

Precision is paramount, especially in industries where materials costs are high. These machines are designed to execute cuts with microscopic accuracy, ensuring that each piece meets the strictest quality standards. By upgrading to a CNC profiler, businesses can guarantee uniform precision that eliminates human limitations that come with manual processes.

Consistency: The Key

Inconsistency in cutting results can lead to wasted materials, time, and resources. CNC profile routers eradicate this concern by delivering unwavering consistency across every cut. For businesses that value uniformity in their products, upgrading to a CNC profile router is a strategic move that eliminates the risk of defects and minimises rework.

Sustainable Practices: Minimising Waste

Upgrading to a CNC profile router contributes to greener practices. These machines optimise material usage, reduce waste, and promote environmentally friendly manufacturing. Not only will this save your business money, but minimising scraps will enhance your business’s ecological footprint and align with the growing demand for eco-conscious solutions.

A Future-Ready Investment

In a landscape where technology shapes the future, investing in an upgrade to a CNC profile router is a strategic move that holds immense value. This upgrade is the pathway to success for businesses seeking to stand out, deliver quality, and embrace innovation.

Partner with the Professionals at AMS

In operation since 1985, AMS has the experience and knowledge to guide you on the best aluminium machinery solutions for your business. We assist with machinery installation, training your team and ongoing servicing to support your crew. We have long term relationships with our customers and enjoy supporting your business growth with the most effective machinery solutions.

If you’re looking for aluminium machinery solutions for your business or want to investigate how you can streamline your processes, contact us at 1300 736 556 or email [email protected].