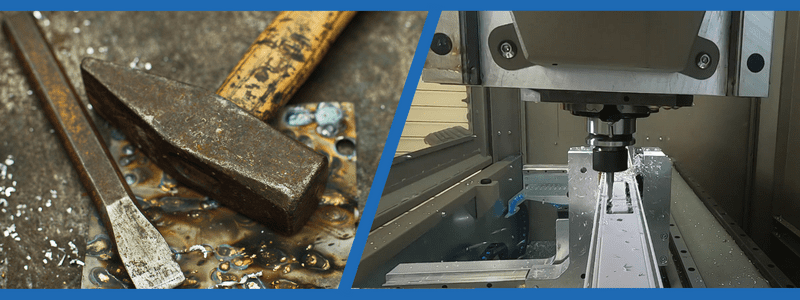

The journey of aluminium fabrication is a story of innovation and technological progress. Each advancement has significantly transformed the manufacturing landscape from the earliest use of hammers and chisels to the sophistication of Computer Numerical Control (CNC) routers. This evolution documents the human ingenuity in pursuing efficiency and precision that has culminated with CNC routers. These versatile powerhouse machines are engineered to utilise software to create custom designs with industrial hardware – allowing one machine to perform a thousand jobs.

The Dawn of Fabrication: Hammer and Chisel

Our story begins with the hammer and chisel, tools that laid the foundation of artisanry. This era was characterised by manual, labour-intensive processes, where the quality and intricacy of the finished product were solely dependent on the skill and finesse of the craftsman. While this method allowed for unique, bespoke creations, it was time-consuming, labour-intensive, and lacked consistency and precision for complex designs.

The Manual Template Router: A Step Towards Mechanisation

The invention of the manual template router marked the first significant leap towards mechanization in aluminium fabrication. By using a physical template to guide the cutting tool, this innovation introduced a new level of consistency and efficiency. It made replicating shapes and designs faster and more accurate, paving the way for increased production capacity. However, the reliance on physical templates and manual operation still limited the complexity of designs and overall flexibility.

The Introduction of NC Routing Machines: Bridging the Gap

As the industry yearned for more precision and efficiency, the advent of Numerical Control (NC) routing machines in the mid-20th century represented a critical bridge between manual methods and the digital age. These machines, controlled by punched tape, offered a glimpse into the future of automated manufacturing. With NC routers, fabricators enjoyed improved reliability and the ability to produce more intricate designs than manual template routers could achieve. Yet, the programming limitations and lack of real-time flexibility highlighted the need for further advancement.

The CNC Router Machine: Augmenting Design and Production with CAM Software

Central to this technological marvel’s capability is integrating CAM (Computer-Aided Manufacturing) software, the vital link between digital designs crafted in CAD (Computer-Aided Design) software and their realisation through precision machining.CAM software takes the detailed designs created in CAD and translates them into G-code, the language CNC routers understand. This translation process is critical, as it dictates every movement, speed, and change in the direction of the cutting tool, ensuring each cut is executed with precision. Through this process, sustainability is promoted through waste minimisation. This level of accuracy facilitates the creation of parts and components with unmatched consistency and quality, hallmark traits of CNC machining.

The adoption of CAM software in the CNC routing process is transformative, allowing for unprecedented design complexity and precision. It enables fabricators to push the boundaries of what can be achieved, from intricate patterns to complex geometrical shapes in aluminium. CAM software optimises the machining process, ensuring efficient material removal and optimal tool paths, essential for maintaining the integrity of the design and material.

In the landscape of aluminium fabrication and beyond, CNC routers, empowered by CAM software, represent a fusion of design innovation and manufacturing excellence. This combination not only elevates capabilities, efficiency, and reliability but also transforms intricate designs from digital concepts into tangible realities with ease and precision previously unimaginable. As such, the CNC router, underpinned by CAM technology, stands not merely as a machine of a thousand uses but as a beacon of future manufacturing possibilities.

Partner with the Professionals at AMS

In operation since 1985, AMS has the experience and knowledge to guide you on the best aluminium machinery solutions for your business. We assist with machinery installation, training your team and ongoing servicing to support your crew. We have long-term relationships with our customers and enjoy supporting your business growth with the most effective machinery solutions.

If you’re looking for aluminium machinery solutions for your business or want to investigate how you can streamline your processes, contact us at 1300 736 556 or email [email protected].