Investing in the right CNC machining centre can significantly improve your production efficiency, accuracy, and material handling. Whether you run a busy fabrication shop or are expanding your capabilities in aluminium or uPVC profile machining, understanding the key differences between machine options is essential.

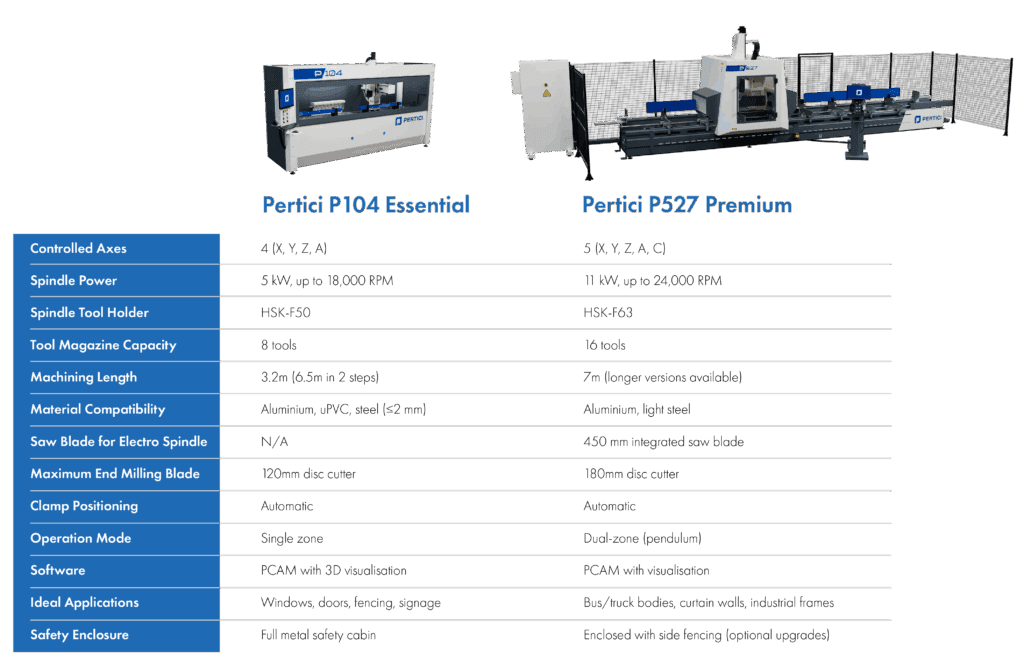

In this article, we explore two high-performing CNC machining centres from Pertici Industries: the P104 Essential and the P527 Premium. Both machines are designed to support precision manufacturing but cater to different scales and workflows.

What to Consider When Choosing a CNC Machining Centre

CNC machining centres vary significantly in their capabilities. It is important to assess your operational requirements and the types of profiles you are processing. Key considerations include:

- Number of controlled axes

- Spindle power and tool change capacity

- Profile length and material type

- Clamp positioning method

- Software compatibility and ease of use

- Floor space and workflow integration

The P104 and P527 both meet high standards for reliability and performance. However, each is optimised for different production environments and outputs.

P104 Essential – Compact Versatility for Light to Medium Fabrication

The P104 Essential is a 4-axis CNC machining centre suited to aluminium, uPVC, and light steel profile processing. It offers a flexible solution for smaller workshops or those transitioning into CNC automation, particularly when space and budget are key considerations.

Best Suited For:

- Custom aluminium window and door manufacturing

- Privacy screens, fencing, and balustrades from cut-to-size profiles

- Louvre systems and architectural trims for internal and external fit-outs

- Signage frames and uPVC display structures

- Short-length architectural profiles including skirtings and pelmets

Key Benefits:

P527 Premium – Power and Automation for Industrial Production

Key Benefits:

The P527 Premium is designed for demanding industrial environments. It offers 5-axis control, dual-zone machining, and a long bed for high-throughput operations that involve complex, large-scale profiles.

Ideal Applications:

- Cutting and trimming aluminium panels for truck and bus bodywork

- Structural framing for curtain walls, façades, and solar supports

- Fabricating chassis and structural steel for trailers or enclosures

- Multi-shift operations where continuous machining is required

Software that Supports Smarter Workflows

Both the P104 and P527 machines are equipped with easy-to-use PCAM software, offering powerful programming capabilities for machinists and operators. Key features include:

This software platform enhances repeatability, reduces setup times, and enables faster job turnarounds, especially for businesses processing multiple profile variations.

Which CNC Machining Centre Fits Your Aluminium Fabrication Needs?

FAQs

Q: What’s the difference between a CNC machining centre and a CNC router?

A: CNC routers are typically designed for lighter materials like wood or plastics. The P104 and P527 are industrial-grade CNC machining centres engineered specifically for aluminium, steel, and uPVC, with higher spindle power and more robust construction.

Want to see full machine specifications? Download the product catalogue here for detailed technical data, layout dimensions, and optional extras.

Q: Can I use my existing design files with these machines?

A: Yes, both machines support industry-standard file formats including DXF, STEP, and NCX via PCAM software.

Q: Is the P527 overkill for smaller workshops?

A: For compact operations, the P104 offers ample capability without the space and cost of a full 5-axis setup. The P527 suits higher workloads where speed and continuous operation are critical. The P527 features a 450mm integrated saw blade on the electro spindle for cutting profiles to length without the need for a tool change, speeding up productivity.

Q: What’s the advantage of dual-zone operation in the P527?

A: Dual zones allow the machine to process a part while the next one is being loaded. This reduces idle time and boosts production efficiency, especially for batch jobs.

Q: What support does AMS provide post-installation?

A: AMS offers local servicing, spare parts, tool kits, installation support, and ongoing technical assistance. Learn more on our Support Services page.

Conclusion

Whether you’re machining light architectural profiles or managing high-volume aluminium fabrication, choosing the right CNC machining centre will influence your productivity, consistency, and flexibility.

The P104 Essential is ideal for compact operations requiring reliable, adaptable performance. For businesses handling complex parts and long profiles, the P527 Premium offers advanced automation, powerful 5-axis control, and built-in efficiency.

For full technical specifications, layout drawings, and optional accessories, download the product catalogue here.

To explore more options, visit our full CNC machinery range, or learn how AMS supports Australian fabricators with installation, servicing, and technical support.

Need personalised advice? Call 1300 736 556 or email [email protected] to speak with our team to help you find the best-fit solution.