Description

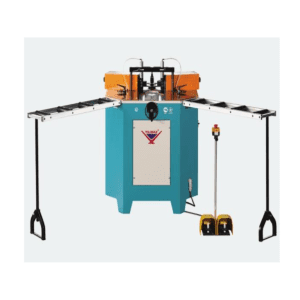

The P104 CNC machining centre with 4 controlled axes is designed to perform milling, drilling, tapping, and end milling operations on bars or workpieces made of aluminium, uPVC, light alloys in general, and steel up to 2 mm thick. Adapt your machining centre to your needs, guaranteeing flexibility and maximum efficiency!

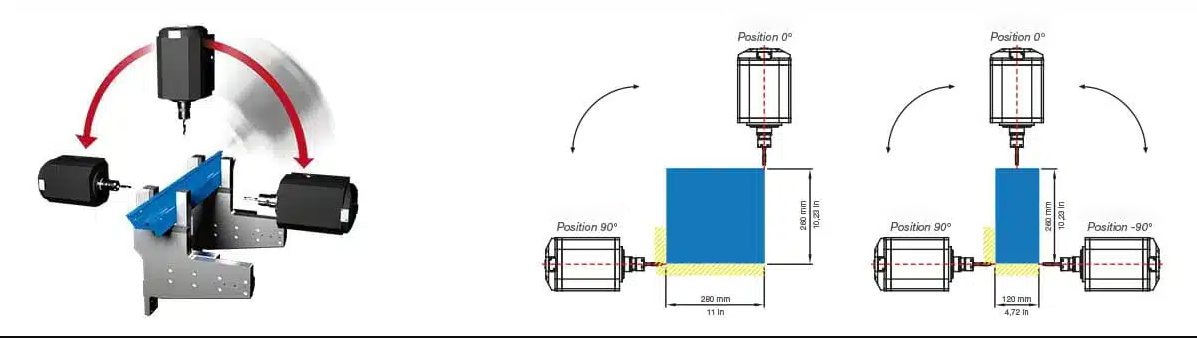

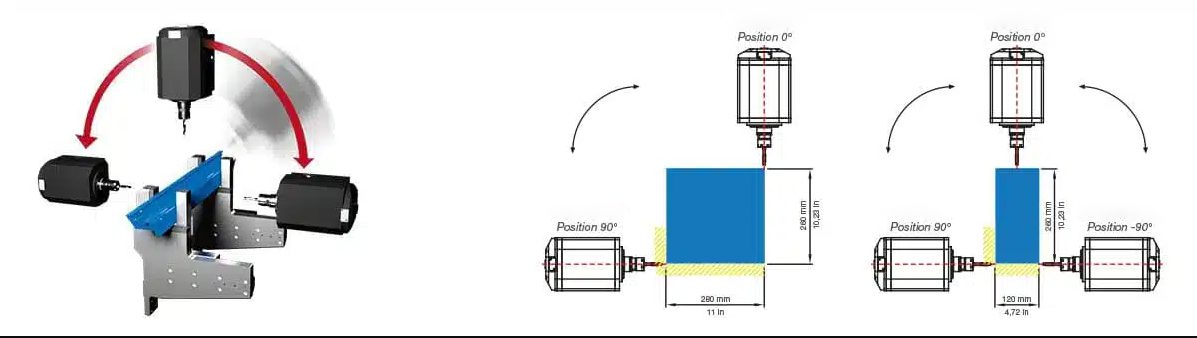

The centre features a pneumatic left-hand zero stop, allowing profiles up to 3.2 m to be machined, with a doubled length available through the optional installation of a second zero stop. The electro-spindle with 5 kW power in S1 and HSK-F50 cone attachment allows machining on the profile at any angle between 0° and 180°.

The P104 machining centre ensures precise and safe operations. The profile clamping is guaranteed by four clamps with reduced overall dimensions, allowing maximum machinability on the three faces of the profile and the loading of even relatively short workpieces. The maximum cross-section of the clamp can accommodate a profile of 225 mm in base and 260 mm in height. The arrangement along the X-axis is a key feature of these centres. Thanks to the mobile carriage, the clamp is hooked and positioned with maximum precision, ensuring optimised positioning over the machining operations of the profile and maximum safety against possible collisions. The P104 machining centre also features an 8-position tool magazine, fixed to the centre of the bed.

With its moving-column machine concept, it is designed for high work rates within a relatively compact overall size. This design not only ensures high productivity but also provides the operator with excellent ergonomics during loading and unloading workpieces, thereby enhancing the overall efficiency of your operations.