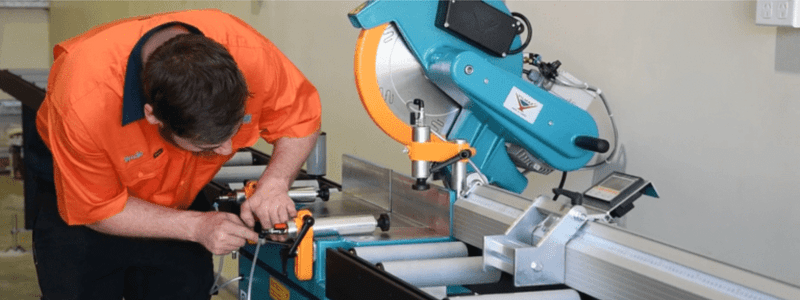

In the world of manufacturing and fabrication, precision and efficiency are paramount. One essential tool that plays a pivotal role in these industries is the aluminium cutting saw. Whether you’re cutting aluminium extrusion for window & door fabrication, aerospace components, or automotive parts, the efficiency and accuracy of your aluminium cutting saw can significantly impact your bottom line. Regularly servicing your aluminium cutting saw is not just a good practice; it’s a strategic investment that can lead to increased profitability and efficiency. In this blog, we will explore the numerous benefits of routine maintenance for these critical pieces of equipment.

1. Enhanced Safety

Safety should always be the top priority in any industrial setting. Aluminium cutting saws can pose significant safety risks if not properly maintained. Regular servicing ensures that all safety mechanisms, such as emergency stop buttons, blade guards, and sensors, are functioning correctly. This minimises the risk of accidents and injuries, reducing downtime due to workplace incidents and potential legal liabilities.

2. Extended Lifespan

Aluminium cutting saws are a substantial investment, and you want to maximise the return on that investment. Regular servicing can significantly extend the lifespan of your equipment. During maintenance, technicians can identify and address issues before they become major problems. This proactive approach can save you from costly repairs or the need to replace the machinery prematurely.

3. Improved Precision and Quality

Precision is vital in industries that rely on aluminium cutting saws. Any deviation from the desired measurements can lead to material waste, rework, and increased production costs. Regular servicing ensures that the saw’s alignment, blade sharpness, and cutting angles are optimized for precise cuts. This, in turn, results in higher-quality finished products and minimises the need for adjustments or corrections.

4. Increased Productivity

Efficiency and productivity go hand in hand. A well-maintained aluminium machinery saw operates at peak performance levels, cutting through aluminium extrusions smoothly and quickly. Reduced downtime due to breakdowns or repairs means more uninterrupted production hours. This translates to higher output, shorter lead times, and the ability to fulfil orders more efficiently.

5. Energy Efficiency

Energy costs are a significant expense in manufacturing and fabrication. An improperly serviced saw may require more energy to function, leading to higher operational costs. Regular maintenance ensures that the machinery operates efficiently, reducing energy consumption and lowering your utility bills.

6. Cost Savings

Many businesses overlook the fact that regular servicing can actually save money in the long run. The cost of routine maintenance is typically much lower than emergency repairs or the replacement of damaged machinery. By investing in preventative maintenance, you can avoid unexpected expenses and budget more effectively.

7. Compliance with Regulations

Depending on your industry, you may be subject to specific regulations and standards regarding machine safety and maintenance. Regular servicing of your aluminium cutting saws helps ensure compliance with these requirements, preventing potential fines and legal issues.

In the competitive world of manufacturing and fabrication, maximizing profitability and efficiency is crucial for success. Regularly servicing your aluminium cutting saws is a wise investment that pays off in numerous ways. From safety improvements to extended equipment lifespan, enhanced precision, increased productivity, energy efficiency, and cost savings, the benefits are undeniable.

By prioritising the maintenance of your machinery, you not only safeguard your workers and reputation but also position your business for long-term growth and profitability. Remember, a well-maintained aluminium machinery saw is not just a tool; it’s a cornerstone of your success.

Partner with the Professionals at AMS

In operation since 1985, AMS has the experience and technical knowledge to support your business, keeping your machinery in great condition. As well as servicing, we also provide new machinery installation and training for your team. We have long-term relationships with our customers and enjoy supporting your business growth with the most effective machinery solutions.

If you’re looking for excellent experienced aluminium machinery support and servicing for your business contact us at 1300 736 556 or email [email protected].